2nd Hand Equipment - Coming soon!

We are now putting the final touches to the World Mining Equipment 2nd Hand market place. If you would like information on this service contact

Separation technology specialist Eriez has published a white paper stating that performance metrics collected from installations of its trunnion magnets worldwide indicate a six-month to one-year payback when compared with trammel screen installations. The report, titled Trunnion Magnet Technology Delivers Quick Payback and written by Eriez Director of Mining and Minerals Processing Jose Marin, explained how trunnion magnets function, highlights their performance advantages, describes retrofitting options, and provides detailed economic justification, including guidelines to assess savings potential. A graph illustrates how kilowatt usage can be reduced, with estimates for a typical 18-ft-diameter mill application resulting in savings of up to $100,000 per year.

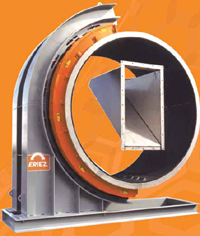

The trunnion magnet system for separating and removing balls, chips or scats in a typical ball/SAG mill operation enables an operation to replace the dead weight of ball magnets with fresh ore. The magnet is mounted at the ball-mill discharge point, replacing the conventional trommel screen. It consists of a barrel or “blind trommel” that is mechanically attached to the trunnion or discharge of a ball mill. The barrel rotates around a fixed assembly of ferrite and rare earth magnets positioned on the outside of the barrel. The stationary magnetic assembly attracts chips and scats to the inside diameter of the barrel. As the ball-mill slurry discharges through the barrel, eight strategically placed lifters inside the barrel carry the ball fragments to the top, where they fall on to a sloping discharge chute.

According to the company, by effectively removing 80% or more of the worn or broken media, the magnet reduces power consumption from the mill drive and prevents expensive damage to other equipment, such as pumps and hydro-cyclones. In addition to removing worn grinding media from the ball mill discharge and saving energy, Eriez said trunnion magnets have other advantages that appeal to SAG mill operators. For example, they eliminate the need for a higher-cost trommel screen and its associated maintenance, they increase mill throughput up to 5%, and many installations increase their mill work index through more efficient grinding.

http://www.eriez.com