2nd Hand Equipment - Coming soon!

We are now putting the final touches to the World Mining Equipment 2nd Hand market place. If you would like information on this service contact

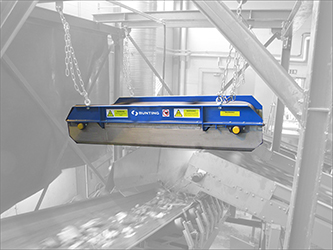

Bunting designed and built the first Permanent Overband Magnets in the early 1980s and has since supplied thousands to companies operating across the world. Permanent Overband Magnets are commonplace in most mines and quarries, however, there are many different designs developed to suit specific applications and understanding an installation is key to selecting the right one.

Bunting’s range of Permanent Overband Magnets includes four different models to suit different installations. The heavy-duty PCB model, the PCB-C compact and lightweight model, the QBC quick-belt change model and the Tri-Polar.

Selecting the correct Overband Magnet, in terms of permanent or electro and the specific model, is dictated by the application. Bunting’s applications engineers assess the ferrous metal separation objective (i.e. the plant being protected); the nature of the tramp ferrous metal (i.e. shape, size, etc.); and the conveyed rock (i.e. size range, burden depth). These criteria assist the team in selecting the optimum Overband Magnet for any given application, says the company.

For more information: https://www.bunting-redditch.com/product-category/magnetic-separation/